As urban landscapes and cultural construction continue to evolve, stainless steel sculptures have become an essential part of modern public aesthetics. Especially medium to large-scale sculptures, known for their grand presence, visual impact, and long-lasting durability, are widely used in city landmarks, parks, commercial areas, cultural centers, and corporate campuses.

Our factory specializes in the design and custom production of medium to large stainless steel sculptures, with expertise in abstract sculptures, animal sculptures, figure sculptures, and large-scale urban landmarks. This article provides a comprehensive breakdown of the entire production process—from initial design to final installation—unveiling the craftsmanship and artistic value behind each “cold” yet expressive piece.

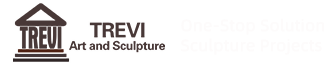

I. Overview of the Production Process

- Concept Design & 3D Modeling

- Internal Structural Framework

- Stainless Steel Sheet Cutting & Forming

- Welding & Shaping

- Grinding, Polishing & Detailing

- Surface Treatment (Mirror, Brushed, Painted, etc.)

- Packaging, Transportation & On-Site Installation

II. Detailed Production Workflow

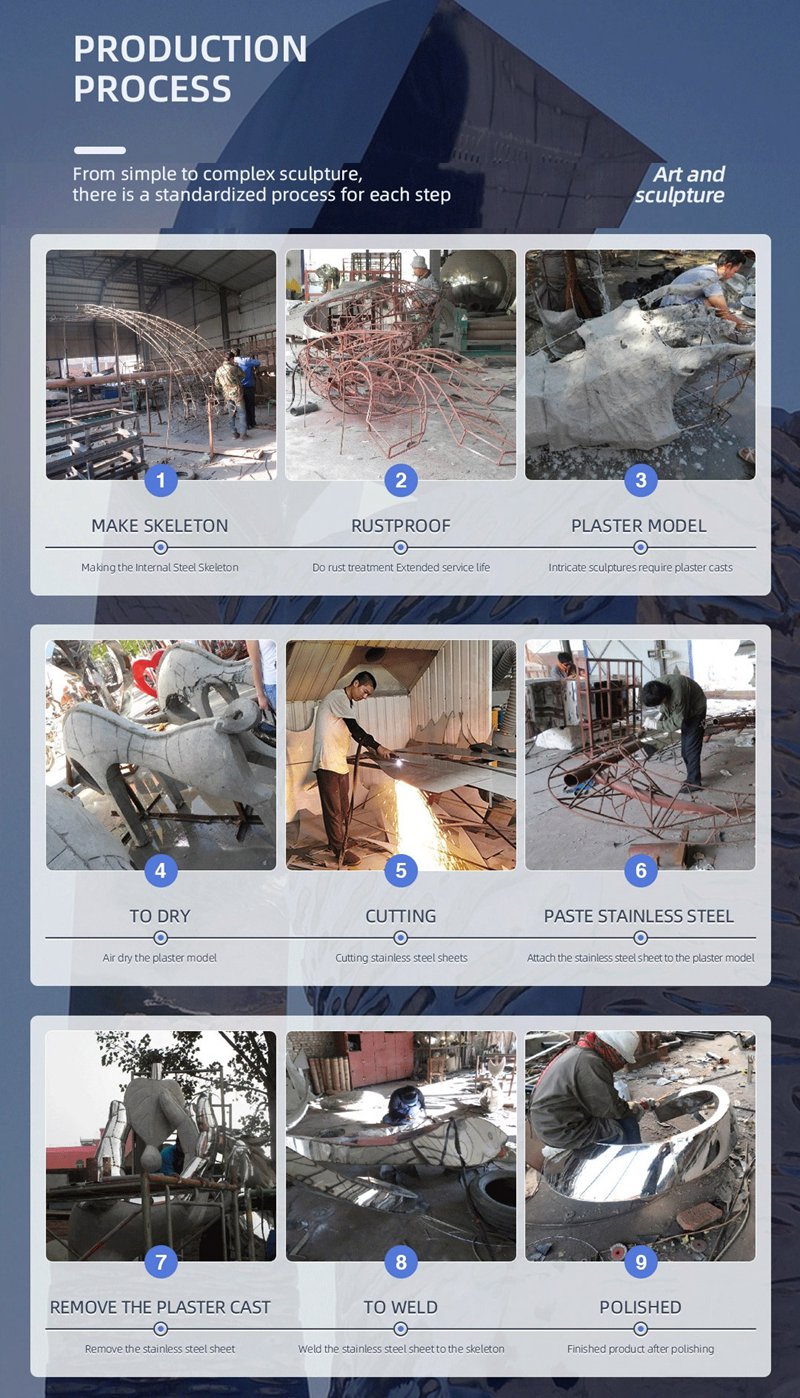

1. Design & Modeling – The Fusion of Art and Structure

Design is the soul of every sculpture project.

- Sketch → 3D Modeling → Structural Division → Technical Drawings

- For large sculptures, factors such as proportion, aesthetics, structural integrity, and environmental fit are all considered.

- Professional software such as Rhino, 3ds Max, and ZBrush is used for precise modeling.

- Foam models or clay maquettes are sometimes created to verify design effects.

2. Internal Framework – The Core of Stability

Structural engineering ensures long-term safety, especially for large outdoor installations.

- Reinforced materials: thick square steel, seamless pipes, angle iron

- Designed according to architectural load-bearing standards

- Strong welding, with embedded parts and anti-wind/seismic reinforcements

- Ensures stability in harsh outdoor environments such as heat, storms, or earthquakes

3. Sheet Cutting & Forming – Precision in Every Piece

- Commonly used: 304/316 stainless steel, thickness 2.0–5.0 mm

- Laser cutting or plasma cutting based on model drawings

- For complex forms: hot bending, rolling, hammering, or mold pressing

- Skilled artisans pre-fit and adjust for seamless alignment

4. Welding & Shaping – Seamless Fusion of Form and Structure

- Primarily uses TIG (Tungsten Inert Gas) welding

- Techniques include butt welding, stitch welding, and full seam welding

- Multiple rounds of shaping to achieve smooth curves and transitions

- Welds are meticulously ground down until fully invisible

5. Polishing & Detailing – Where Quality Shines

- Multi-stage sanding from 80 to 2000 grit

- Focused polishing on weld zones, edges, and curved surfaces

- The tactile and visual finish of the sculpture depends heavily on this stage

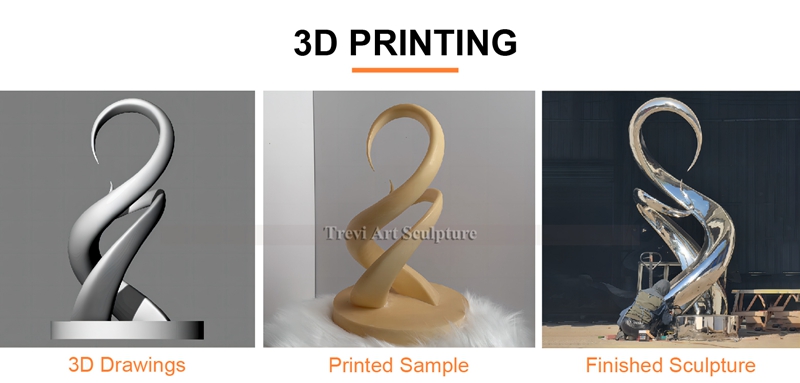

6. Surface Treatment – Defining the Style and Finish

Surface treatments vary based on design and client preference:

- Mirror Polishing– High-reflective modern finish

- Brushed Finish– Matte, elegant, fingerprint-resistant

- Sandblasting / Oxidizing / Painting– Artistic and colored finishes, antique or copper-like effects

- High-Temperature Fluorocarbon or Automotive Paint– Ideal for colorful animal or figure sculptures

7. Coating & Protection – Extending Durability

- For colored pieces: automotive paint, fluorocarbon coating, or baked finishes

- Transparent top coats (e.g., clear lacquer) protect against fingerprints and watermarks

- UV-resistant and anti-corrosion coatings are recommended for outdoor installations

8. Transportation & Installation

- Sculptures are packaged with wooden crates, foam padding, and structural supports

- Common installation methods:

- Welded onto embedded steel plates

- Anchored with bolts

- Integrated into base structures

- Cranes or lifting equipment may be required for large or high-altitude installations

III. Common Sculpture Types & Craft Features

| Type | Characteristics | Surface Treatment Suggestion |

| Urban Landmark | Large-scale, complex structure | Mirror polish or painted |

| Landscape Sculpture | Organic shape, integrates with nature | Brushed or matte finish |

| Commercial Art Piece | Eye-catching, high artistic value | Colorful paint or mirror finish |

| Cultural/Educational | Thematic, meaningful | Sandblasted or brushed with text |

| Abstract Sculpture | Minimalist or geometric | Brushed + spot-welded assembly |

IV. Popular Sculpture Categories

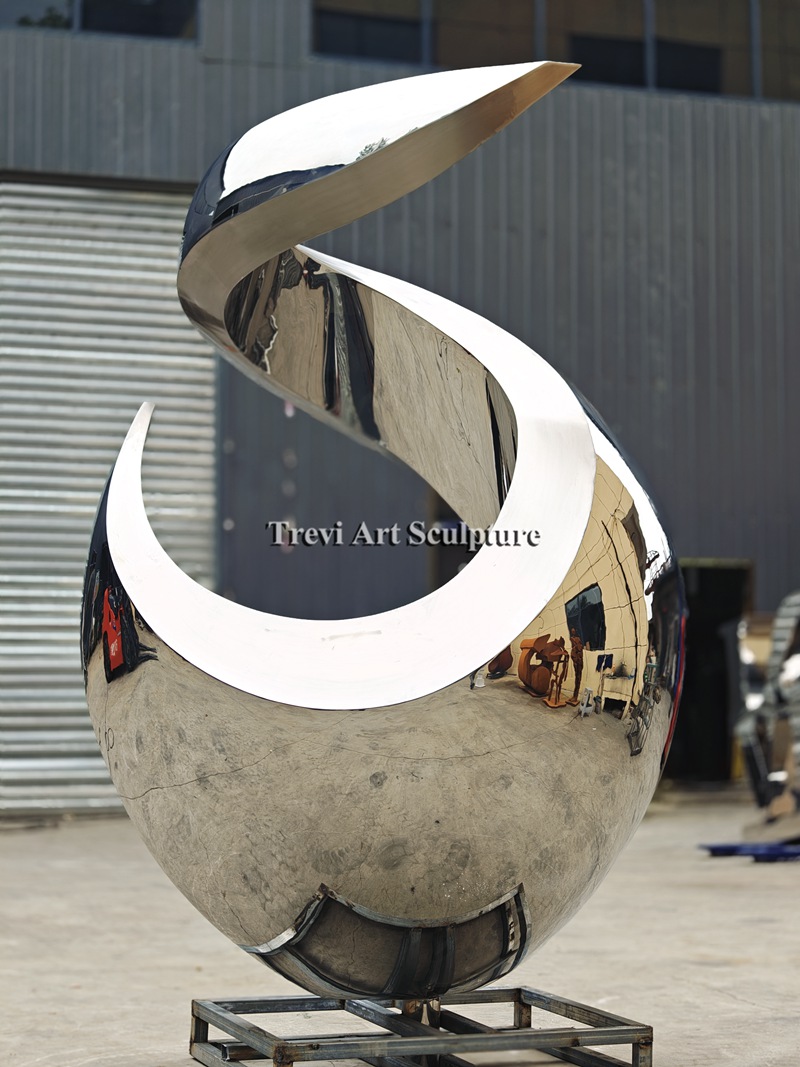

1. Abstract Stainless Steel Sculptures

- Focus on form, rhythm, and spatial dynamics

- Ideal for plazas, office entrances, and art spaces

- Often finished in mirror polish or gradient color spray

2. Animal Sculptures

- Subjects include lions, tigers, horses, elephants, phoenixes, and marine life

- Can be realistic, stylized, or geometric

- Requires precise shaping and expressive postures, often with painted or antique finishes

3. Figure Sculptures

- Found in campuses, memorials, and cultural zones

- Emphasis on anatomical accuracy and facial expression

- Best suited for brushed with localized color, or mirror / antique bronze finish

4. Large Urban Landmark Sculptures

- Typically 5m to 30m tall

- Requires structural engineering, safety certifications, and on-site management

- Used as visual anchors in city squares, airports, and exhibition centers

- Our team provides end-to-end services: design, calculation, fabrication, and installation

V. Key Advantages of Stainless Steel Sculptures

✅ Highly corrosion-resistant and weatherproof for outdoor display

✅ High design flexibility: suitable for modern, abstract, or classical styles

✅ Diverse surface treatments for visual impact and low maintenance

✅ Proven craftsmanship for both mass production and unique, custom creations

Stainless steel sculptures are not only artistic landmarks but also symbols of craftsmanship where industrial precision meets aesthetic sensibility. From each weld and polish to the final protective coating, every detail reflects our dedication to quality and artistry.

If you’re seeking a professional stainless steel sculpture manufacturer, Trevi offers a complete in-house production system, experienced technical teams, and state-of-the-art equipment. We welcome custom orders based on your design or concept — let us help you create a one-of-a-kind sculpture that stands the test of time.